DUAL BATTERY CHARGING MADE EASY

Dual battery charging made easy

Protects electronics on house battery circuit from engine start-up spikes

Fully automatic

BEP’s Unique VSR

Modern charging systems must be able to safely charge two or more different types of batteries from one engine.

Now, thanks to BEP’s unique VSR (Voltage Sensitive Relay) boat owners can enjoy the benefits of a fully charged engine starting batteries and deep cycle house batteries with one easy-to-install charging system.

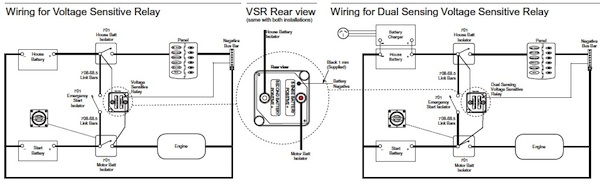

710-125A (SINGLE SENSE) VSR OPERATION

The Voltage Sensitive Relay (VSR) allows two batteries to be charged at the same time. When the engine is started and the start battery reaches 13.7 volts, the VSR engages, allowing two battery banks (start and house) to be charged simultaneously. When the voltage drops below 12.8 volts (eg the engine is stopped), the VSR disengages, separating the batteries.

This system eliminates the possibility of draining the wrong battery and protects sensitive electronic equipment powered from the house battery from harmful engine start-up spikes.

710-125A-DS (DUAL SENSE) VSR OPERATION

Same as the 710-125A with the added feature of dual sensing.

This allows the unit to sense the voltage of both batteries that it is connected between. If either battery is receiving a charge the VSR will activate paralleling the two battery banks.

The 710-125A-DS is designed for situations where a battery charger or second charging source is used in the house battery.

Frequently asked questions

Q: To which side of the battery switch should the VSR be wired?

A: It is vital to follow the wiring installation diagram which shows the correct connection to the master switch. BEP only recommends the supplied option. Other options can lead to accelerated battery discharge as the sense circuit draws 0.01 Amps continuously. The output wire of the VSR should always be connected to the battery side of the House battery switch to ensure true isolation of house circuits if the VSR is engaged.

Q: Why does the LED stay on after the engine is turned off?

A: System voltage has not dropped below 12.8 V DC due to battery charging. VSR will disengage once residual battery voltage drops below 12.8 V DC.

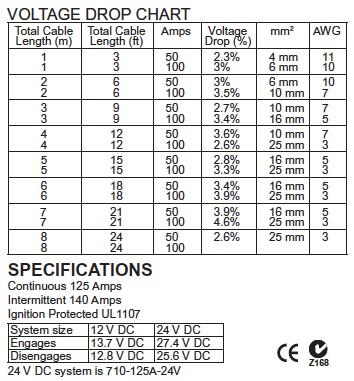

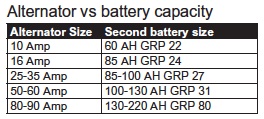

Q: How do I ensure that the correct size of the battery is matched to my VSR?

A: See the battery sizing chart on the next page.

Q: Why does my VSR ‘chatter’?

A: Because the charging system is too small for the batteries and this is not allowing the VSR to work properly. Instead, once the starting battery has reached the right voltage and the house battery is connected the systems voltage is ‘caving down’ below 12.7 volts and the relay is automatically disconnecting. The voltage then rises, the relay re-engages; then the voltage drops the relay disengages and the ‘chattering’ sound is heard as the relay quickly switches in and out. Refer to the battery sizing chart on the next page.

BEFORE INSTALLING

IMPORTANT

Do not use any type of corrosion inhibiting spray such as CRC, INOX, etc. on any part of this unit. These units are hermetically sealed so do not require any other form of sealing. The studs have been tinned to inhibit corrosion, use petroleum grease if required (on metal parts only).

ENSURING CORRECT BATTERY SIZING:

The charging system must be correctly sized to the batteries. If the charging system is too small for the batteries the VSR will not work properly.

How the VSR works

Once the starting battery’s voltage rises to above 13.7 VDC, the VSR switches to charge both batteries in parallel, when the voltage drops below 12.8 V DC the VSR disengages. A buzzer like sound can be heard as the relay quickly switches in and out.

Disengagement can occur at idle (low amps out due to slow speed of alternator) or if the house battery is at a low charge. An increase of the engine’s RPM will increase the alternator output and hold up the voltage.

INSTALLATION

Connect the VSR to the back of the battery isolating switches, ensuring that the battery cable is correctly sized. This will ensure good current flow to the battery, reducing unwanted voltage drops to the VSR. The LED on the front of the VSR should be visible, as it will instantly show when it is in operation.

Note: When using a VSR in conjunction with a high-performance voltage regulator (eg Next Step Regulator) the regulator sense wire must go to the same point as the sense for the VSR ie the start battery.

Remove base to expose studs and negative lead. Cut out cable access slots:

1) With a hacksaw blade, cut vertical lines into the sidewalls of the VSR case, as shown by dashed lines (approximate positions). Stop cutting at the point where the plastic steps up to a thicker wall. Take care not to damage the circuit board with the blade.

2) Once the two slots have been cut, with a pair of pliers bend the middle section (between the two slots) inwards until it snaps away from the main body (Along horizontal dashed lines)

Use countersunk screws for fastening base down.

Use Panhead screws for fastening the VSR onto the base.