by Shurflo

The SHURflo Accumulator tank is a bladder type pressure storage vessel and/or pulsation dampening device designed to hold water under pressure.

The accumulator tank provides additional water storage to assist the pump in meeting the total demands of the system. It extends pump life by eliminating pump pulsating on/off. Makes water available at a moment’s notice w/o cycling the pump.

• The standard accumulator is pre-charged to 20 psi [1.4 bar] at the factory for ground shipment. Do not exceed this pressure for long-term storage, shipping, or during system non-use. Accumulators with more than 40 psi [2.7 bar] pre-charge and no liquid pressure may damage the bladder.

• It is recommended the pre-charge be checked on a monthly basis. Use a standard tire pressure gauge to check the pressure. The pre-charge valve stem cap MUST be tight to prevent air leakage.

• The accumulator may be placed anywhere in the pressurized side of the plumbing. The ports are non-directional inflow and do not have to be plumbed inline (one side can be plugged).

• It can be mounted in any position. However, for complete sanitizing/winterizing, the recommended mounting position is with the pre-charge valve stem up. Do not freeze or mount near a high heat source.

• Models with 1/2-14 ports: Insert the rubber washers in each port. Threaded fittings (plastic/nylon only) should be torqued approximately 1/2 to 1 turn after hand-tightened. Never exceed 6 ft/lbs [88 Nm] of torque on the ports. Plumb the system using high pressure (2x pump rating), braided, flexible tubing to minimize vibration/noise.

RV/MARINE APPLICATIONS

The accumulator contributes to longer pump life, less noise, less amperage draw, and reduced water pulsation. The most efficient use of the accumulator occurs with the pre-charge set at the SAME pressure as the pump’s pressure switch “turn on” setting. Typically, a 40 psi [2.7 bar] pump will turn on at 20 psi [1.4 bar]. Therefore, the pre-charge should also be 20 psi [1.4 bar]. The pre-charge MUST be set in a “static” condition (pump off and at least one water fixture opened).

Approximately 15% of the total volume will be stored liquid. Depending on pre-charge pressure to the accumulator, in relation to the pump turn on/off pressures, the stored liquid is about 2 to 4 oz. [60-120 ml]. If the accumulator tank pre-charge exceeds the pump turn on pressure, the liquid volume is reduced.

BEVERAGE APPLICATIONS

For applications requiring an intermittent flow rate at a given pressure, the proper pre-charge is the minimum pressure required at the dispense valve. For example, if a system requires a minimum pressure of 30 psi [2.0 bar] (for correct Brix, etc.), the pre-charge should be set at 30 psi [2.0 bar] to permit the most reserve storage capacity.

WATER HAMMER APPLICATIONS

When used as a dampening device/water hammer or noise suppressor, the pre-charge should be set at the operating (dynamic) pressure. Place a gauge in the offending plumbing where the accumulator can be mounted. Adjust the valve so the noise is generated and read the pressure. Set the pre-charge to the observed pressure, remove the gauge, and install the accumulator.

Refer to SHURflo Service Bulletin #1024 for application information.

Troubleshooting

| SYMPTOMS | POSSABLE SOLUTIONS |

| Does not function; pump cycles rapidly |

Check air pressure. Add or remove air as necessary. |

| Water leaks from the valve | The diaphragm is torn or has a hole. Replace accumulator. |

| Does not hold air pressure | Screws loose, air valve, torn/hole in the diaphragm. Replace accumulator. |

| Leaks from fittings or ports | Check the fitting connection. Ports must seal on the internal port taper, Ports should not be sealed on threads with NPT fittings |

TESTING AIR PRESSURE

Check air pressure with the pump off and one or more faucets open [no water pressure in the system]. Adjust the pressure as needed. If the unit leaks water from the air valve or does not hold pressure, the unit must be replaced.

NOTE: There are no replacement parts or kits for this accumulator. If it is not working, it must be removed or replaced.

WINTERIZING

To winterize, drain all water from the system. Blow system out with low-pressure air, or add potable water anti-freeze. Never use automotive anti-freeze. Death or severe injury can occur.

SPECIFICATIONS

| Maximum Working Pressure | 125 psi [25 bar] |

| Pre-Charge Pressure: | Models 182-100 & 182-200: 30 psi [2.07 bar] |

| Models 182-102 & 182-202: 20 psi [1.4 bar] | |

| Total Volume: (gas/liquid): | 21 oz. [620 ml] |

| Temperature Range: | 34-120° F [1-49°C] |

| Diameter: | 3 3/4” [95 mm] |

| Length: | 8 3/4” [22 cm] |

| Listings: | NSF listed |

| Housing Material: | Nylon |

| Bladder Material: | Butyl |

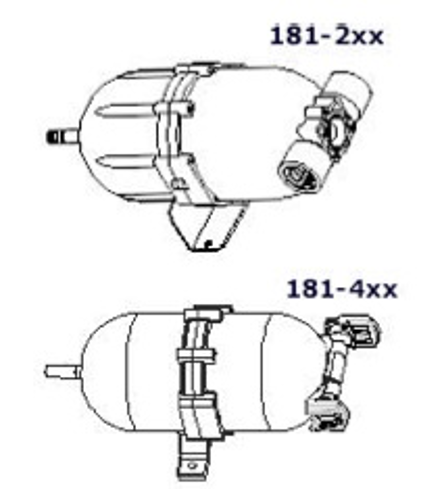

| Threaded Ports:(-201, -202, -203) | 1/2-14F-NPT |

| Snap Fit Ports Fittings:(-4xx) | Available in Nylon or SS 1/4”, 3/8” and 1/2” barb, straight or 90° elbow. A 3/8” straight John Guest adapter is also available. Refer to Beverage Catalog # MS-060-062 for fitting #s. Std. fittings supplied with SHURflo pumps are 3/8″ barb fittings. |

| Mounting Bracket: (std on -4xx / optional on 2xx series) | Two 7/32″ [5.3 mm] φ holes at 4-1/16″ [103 mm] centerline apart |