1. PREFACE

This is a discussion of the theory of leveling a vehicle. Because there are some differences between leveling a motorized and non-motorize vehicle, the detailed explanation for leveling each one will be discussed separately.

Leveling the vehicle is just what it says, some type of jacks attached to the frame of the vehicle or the airbags of an air suspension is used to move the frame of the vehicle up and/or down to put the vehicle into a level position. An important thing to remember about leveling a vehicle is that most vehicles are flexible but that flexibility is not unlimited. Damage can occur to a vehicle if it is twisted too far. Twisting can happen when one corner of the vehicle is lifted or lowered too far.

2. BASIC LEVELING

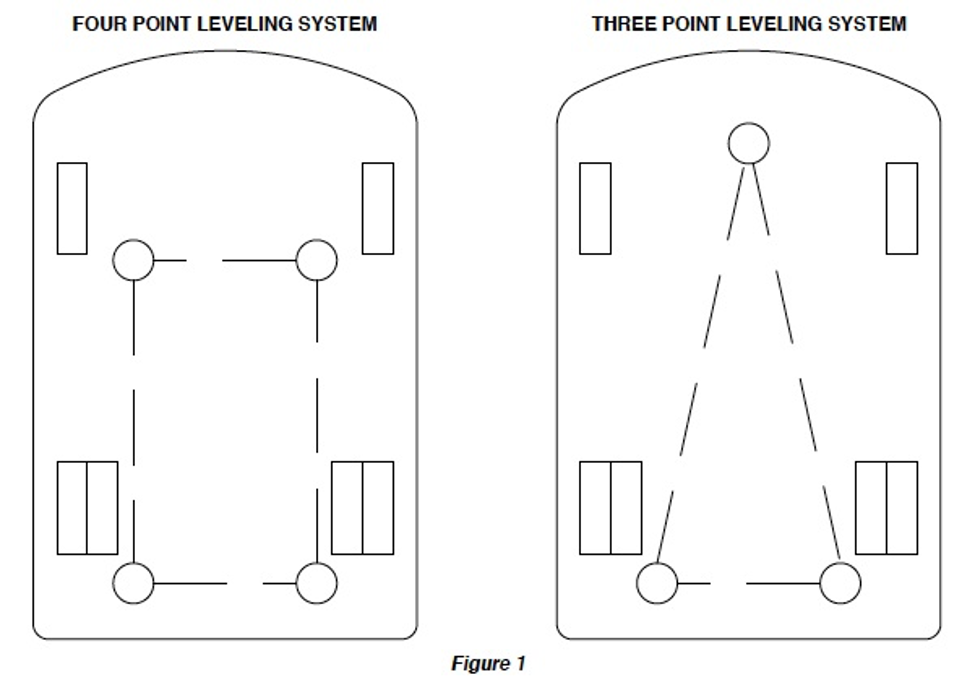

2-1 Four-point vs. three-point leveling. There are two basic types of leveling, the three-point triangular system, and the four-point rectangular system.

Although there is some validity to the concept that leveling a three-point triangle is easier than leveling a four-point rectangle, this is really only true if you are dealing with a flat, solid piece of equipment truly supported at only three points. There are several problems with using a three-point leveling system on a vehicle. One problem is that vehicles are flexible, some much more than others. Another problem is with three jacks you really have a five-point system. Look at the above drawing for the three-point system. You not only have the one jack at the front but also the two suspension points. Many parking areas will put a vehicle into a twisted position or a front corner low position. Three-point leveling systems have a hard time dealing with these situations. When a corner is low, a side must be lifted and also the front or rear. (Or lower, depending on the type of leveling system.)

With only three jacks, any side lift must be made with only a rear jack. Then the front of the vehicle must try to pivot on the front suspension or the front jack. Because of the flexibility of the vehicle, the rear corner may have to be lifted farther than necessary to try to bring the one front corner of the vehicle up to a level position with the other front corner. One problem with that is now the rear corner of the vehicle may be too high. The two rear corners will not be level with each other and the front will have to be lifted more to make the vehicle level front to rear.

Another problem with this is if the front jack is on the ground when lifting a rear corner, the front of the vehicle has to try to pivot on the front jack. Either the jack mounting must flex or the foot of the jack has to move. If the front jack is not extended, the front of the vehicle is trying to pivot on the suspension. When trying to raise one front corner, the opposite side suspension will try to resist this movement. This can be even worse with an air suspension. With an air suspension, the air is dumped from the airbags before leveling. There will be no give on the opposite side. One way suspension interference can be solved is by lifting the front of the vehicle until the tires and suspension are not interfering with the movement of the vehicle while leveling. Having both front tires off the ground is not a very good solution. The stability of the vehicle will be decreased and the rear of the vehicle may have to be lifted quite high to level the vehicle front to rear. The stability of the vehicle will be decreased and the rear of the vehicle may have to be lifted quite high to level the vehicle front to rear.

In the drawings on the previous page, note that with a four-point system the jacks are located at each point of the suspension. With a three-point system, the front jack is between the two points of the front suspension. Vehicles are designed to flex at the suspension points, not between them. When a vehicle with a four-point leveling system has a low front corner, there is a jack (or airbag with air leveling) to help raise the front corner. The four-point system does not depend on the rear jacks alone to lift the sides of a vehicle. There is also the issue of stability. Advocates of the three-point system use the three-legged milking stool comparison. Shorten one leg of the three-legged stool and the stool still sits solid. Shorten one leg of a chair with four legs and the chair is wobbly. This is certainly true of stools and chairs but vehicles are not stools and chairs. With stools and chairs, you are supporting solid surfaces.

You have to remember, vehicles are flexible. Refer to the figures on the previous page. Common sense will tell you which example will be more stable if all the jacks of the system are on the ground. If a jack is not on the ground, the stability of the vehicle will suffer, but this will be true of either system. With a three-point system, only having a center jack at the front will allow some movement side to side at the front. The higher the vehicle is lifted, the more pronounced this will be. Did anyone notice that when vehicle manufacturers started installing room extensions, some vehicles that previously used three-point systems either went to four-point systems or moved the front jack off-center to the side that had a room extension?

In one school some time ago, I had the three point-four point argument with a student. His final argument, when he had not won any of the other arguments, was that a manufacturer that was selling three-point leveling systems had been putting hydraulic outriggers on cranes for many years thus they must know what they are doing. I thought it was nice of him to win the final argument for me. I just asked him when was the last time he saw a crane with a three-point outrigger system. He didn’t have much to say about the rest of the school.

It is not that a three-point leveling system can’t work or that you can’t twist a vehicle with a four-point system. With manually-controlled systems or even computerized systems that offer manual control, the system operator can create twisting problems for the vehicle by manipulating the controls to extend or retract jacks improperly. Air leveling systems have some safeties built-in, but again, the operator can manipulate the controls to create twisting problems. Over the forty years that HWH has been building leveling systems, we have produced both three-point and four-point systems. We just understand that the inherent problems that can be caused by a three-point system can be conquered with the four-point leveling system as long as the system is operated properly.

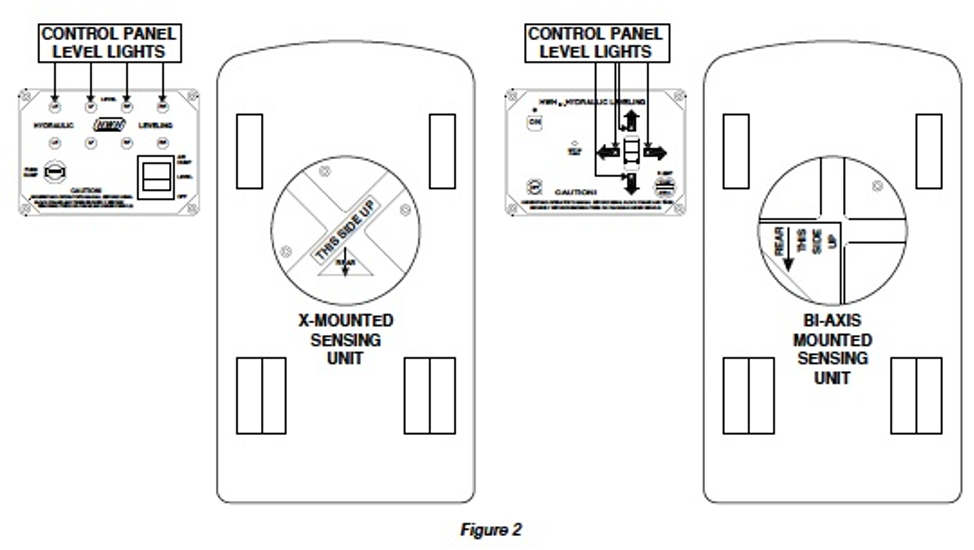

2-2 Bi-axis© leveling. Bi-axis leveling is raising or lowering two corners of the vehicle at one time to level a vehicle along its front to rear axis and its side to side axis. With hydraulic leveling, the system will always use two jacks at a time for leveling; both front jacks, both rear jacks, the left side front, and rear jacks or the right side front and rear jacks. Air leveling systems use the suspension airbags to raise or lower the corners of the vehicle. As with hydraulic leveling, air leveling systems raise or lower two corners of the vehicle at the same time to level the vehicle.

The original HWH hydraulic leveling systems, lever controlled and computer-controlled, all incorporated individual control of the jacks for leveling. The level sensing units and level indicator lights were arranged to show corners of the vehicle (left front, right front, right rear and left rear) that needed to be raised to achieve a level position.

Important: The mercury-filled sensing units represented in the above drawings are not available anymore. They were used strictly for the visual effect. The electronic sensing units that are now used accomplish the same tasks but do it with hardware and programming. Bi-axis style leveling was first introduced in the mid-1980s with a version of the 400 series, paddle switch controlled automatic leveling system. Bi-axis systems have sensing units and level indicator light arrangements that direct leveling movements to the axis’s of the vehicle; front, rear, left side and right side.

The Bi-axis 400 series system along with the 500/510 touch panel systems, the next series of leveling systems, would control two jacks or corners of the vehicle at a time in the manual mode of operation but the computerized programs could control 1, 2 or 3 jacks or corners depending on the type of suspension and which leveling indicators were on. The use of two jacks or corners at all times during the leveling procedure, manual or automatic, was introduced with the 610 series leveling system in 1993.

Although the 610 series system has undergone several renovations, the 610 Central Grounded system, the 625 series system and the present day 625S single-step system, the same basic two corners at a time leveling procedure is still in use. The original 4 levers (100/110) manual controlled system was also replaced (for the most part) with the Joystick (200/225) manual controlled, Bi-axis leveling system in the early 1990s. Although the 4 lever systems are still available, touch panel style systems are only available as Bi-axis systems.

The 310 and 325 manual controlled touch panel systems were also only available as Bi-axis systems. It is important to note that due to specific applications or vehicle manufacturer’s request, there are variations to the Bi-axis systems that may allow single jack or corner control. The number of these systems and their usage will be very low and are usually on specialty vehicles or trailers. You may never run into one of these systems but it is possible that you may encounter an HWH system that does not strictly adhere to the Bi-axis leveling principles.

3. LEVELING A VEHICLE

3-1 General information. It is important that the information and procedures discussed in this section are not confused with information about leveling systems supplied by other manufacturers. All information and procedures discussed in this section are specific to HWH leveling systems and most likely are different than the leveling procedures used by other manufacturers.

To start with, it is important to understand all vehicles, motorized or towable, have some type of suspension. These suspensions utilize some type of spring, torsion assembly, airbag arrangement or a combination these. Any vehicle can be equipped with a hydraulic jack leveling system but only a vehicle with a complete airbag suspension can use an air leveling system.

One difference between the two systems is a hydraulic jack leveling system can only level by raising the vehicle. And yes, if a side or end is raised too far, it could be lowered back down but this would not be the normal leveling procedure. With an air leveling system, a high end or side can be lowered to achieve a level position. Most vehicles with an HWH air leveling system are programmed to try to level the vehicle by lowering first. It is important to note that there have been quite a few different leveling programs over the years, especially for air leveling systems, even on recent vehicles by the request of the owner or vehicle manufacturer. It is very possible that you may run into one of these systems. It is important to contact HWH for assistance when you run into a system that behaves differently than what would be considered normal.

Another difference between the two systems is stability. Although there is a misconception with some people that a vehicle with jacks should be rock solid with no movement, vehicles with jacks certainly are more stable than a vehicle without jacks that is supported only with the airbags. Air leveling systems only level the vehicle, hydraulic leveling systems-level and stabilize the vehicle. It is important to understand that vehicles supported on jacks will still have some movement. Because of vehicle construction, mounting locations for the jacks and how high the vehicle has been raised, the stability of two vehicles may vary. The stability of the same vehicle may vary simply because of different parking locations.

The leveling procedures for hydraulic jack leveling systems also vary slightly with suspension type, spring or airbag. Torsion suspensions are treated as a spring suspension. When a vehicle has an air suspension, the air in the airbags must be completely exhausted before the leveling procedure begins. The reason for this is explained in detail in “Air suspensions and HWH” in the “General HWH information” section of the HWH online technical school. On a vehicle with a spring suspension, the suspension will “give” some while the vehicle is lifted during the leveling procedure. With an air suspension, there is no “give” after the air has been exhausted from the airbags. It is more like moving a solid platform around while trying to level it.

Leveling is also different for motorized and towable vehicles. Motorized vehicles have four suspension points. Towable vehicles only have two suspension points, a right side and left side suspension somewhere on the rear half of the vehicle. Also, the landing gear for a towable vehicle is usually part of the leveling system and the landing gear is normally on the ground, supporting the vehicle before the leveling procedure is started, no matter what position the vehicle is parked in. We will discuss the leveling procedure for the two types of vehicles separately. 3-2 Leveling a motorized vehicle.

This section will deal with the basic leveling procedure and not single out any one type of system. We will only deal with present-day systems in this section. Specific leveling procedures for the different air and hydraulic leveling systems, new and old, are discussed in the “Motorcoach and motorized vehicle” section of the HWH online technical school. 3-2.1 Hydraulic leveling. The basic procedure for hydraulic leveling is the same for lever controls, manual push-button controls or automatic controls. There are two variations that change the basic procedures.

The first variation is suspension type, air or spring. The second variation is jack style, straight-acting or kicks down. These variations don’t actually “change” the procedures; they just add an extra step. With an air suspension, the air in the airbags must be exhausted before leveling takes place. With kick-down jacks, the jacks must be extended to the vertical position before the leveling procedure begins. The following is the leveling procedure:

1. The ignition must be on. The parking brake must be set. 625 single step systems can be used manually at this time without pushing the level button.

2. Turn the control/touch panel on. This will be a rocker switch for lever systems and an I or HYD button for touch panel controlled, manual or automatic, systems. The single-step systems have a LEVEL button. Single-step systems do not have to be turned on. The LEVEL button will activate the auto level mode on the first push if the ignition is on and the parking brake is set.

3. If the system has kick-down jacks, place the jacks in the vertical position at this time. Manual systems use the front and rear extend controls. With automatic systems, push the I/HYD button a second time. 625 single step systems are not available with kick-down jacks. Automatic systems will put the jacks in a vertical position going clockwise around the vehicle starting with the left front jack. Do not proceed until all four red jack down warning lights are on. The automatic system will not proceed unless all four warning lights are on.

4. If the vehicle has an air suspension, the air is dumped from the airbags at this time. If the leveling system is a manual system, or an automatic system is being used manually, push the “DUMP” button to exhaust the air. If the suspension uses an HWH air dump system, the “DUMP” button must be held until all the air is exhausted. If the suspension has a pilot dump system, the “DUMP” button can be released; the suspension will continue to dump the air. Do not proceed until you cannot hear air exhausting from the system. If the leveling system is an automatic system, the air will be exhausted from the bags when the HYD/LEVEL button is pushed to start the leveling mode. There will be a delay of about 20 seconds after the button is pushed before the leveling procedure is started.

5. The leveling process begins. With an automatic system, push the I/HYD/LEVEL button to start the leveling process. This will be the first push with a single step system, a second push for a non-single step system with straight-acting jacks and the third push for a system with kick-down jacks. (Air dump will start at this time if applicable. There will be a 20-second delay before the jacks start to extend.) Leveling is accomplished by extending jack pairs as needed according to any lit yellow level lights. A lit yellow level light indicates a low side or end of the vehicle. Two lit yellow level lights mean a corner is low. There should never be three lit yellow level lights or opposing yellow level lights. If a side level light is lit, an automatic system will extend that jack pair until the light goes out. The system will then move to a lit front or rear level light is necessary. If a front or rear level light is lit, the system will extend that jack pair until the level light goes out. If a side level light comes on while extending a front or rear pair of jacks, the system will ignore that light until the front or rear light goes out.

The system will then go back to the sidelight and extend that jack pair as needed to put the level light out. The same procedure should be followed by manual controlled systems. You have to push and hold the lever or UP ARROW until the level light goes out. When all four yellow level lights are out, the vehicle is level within the tolerances of the level sensing unit.

6. The stabilizing procedure. Although technically, the stabilizing process is not needed to level a vehicle, it should be considered part of the complete leveling process. In most cases, when the leveling process is finished, there will be one or two jacks that have not extended to the ground. Stabilizing a vehicle consists of extending jacks to the ground that were not used during the leveling process.

With an automatic system, the stabilizing process is part of the leveling program. As soon as the last yellow level light is out, the system automatically goes to the stabilizing process. The system looks at individual jack pressure switches to know which jacks need to be extended to stabilize the vehicle. When all the jack pressure switches are on, the computer recognizes the leveling procedure is finished and shuts the system off. Stabilizing the vehicle with a manually controlled system has to be done by the operator. When the yellow level lights are all out the operator has to manually extend remaining jacks to the ground. The front or rear extend positions should be used for stabilizing. If a front or rear jack is already on the ground, the fluid will be directed to the proper jack, the fluid following the path of least resistance.

Check valve arrangements in the manifolds make this possible. There are no indicator lights or pressure switches to let the operator know when a jack reaches the ground. The operator will have to rely on feeling a “bump” when the jack reaches the ground or have someone watch for this. The important thing to remember about stabilizing a vehicle is that the stabilizing jacks must not only touch the ground but also lift the vehicle slightly; at least ¾ inch but not more than 1 ½ inches. If the jack does not lift slightly, thermal contraction of the fluid can cause the jack to “retract” slightly. The vehicle will seem to be less stable if the air temperature becomes lower, which it usually does at night.

7. Excess slope. Only automatic systems have an EXCESS SLOPE light. Excess slope means the system cannot level the vehicle. If one or two jacks reach full extension and the yellow level light remains on, a pressure switch signals the system processor and the leveling procedure is stopped. The system sits idle with the EXCESS SLOPE light on. The system will not stabilize the vehicle. One or two jacks may not be on the ground. Manual systems or manual operation of an automatic system will have no excess slope indication. The operator will have to recognize the jacks will not extend more and the level lights are still on.

8. Retracting the jacks. The only rule for retracting the jacks is to let the store mode cycle through completely. Touch panel systems will turn the system off automatically with a delay after all four red jack down warning lights are off. Lever controlled systems should have the levers in the store position at all times when the vehicle is not on the jacks.

3-2.2 Air leveling. There are two main differences between air and hydraulic leveling. With air leveling, you can lower and raise the vehicle to level it and there is no stabilizing procedure with air leveling. The following air leveling procedure is for present-day systems. Past and future systems may have different programming.

1. The ignition must be on and the parking brake must be set. Air leveling works best if the vehicle engine is running so the engine air compressor is supplying air to the suspension.

2. Turn the touch panel on. Push the AIR button one time. This turns the system on. The system can now be used manually if desired.

3. Push the AIR button a second time. This starts the automatic leveling process. Leveling is accomplished by deflating or inflating airbags as needed according to any lit yellow level lights. A lit yellow level light indicates a low side or end of the vehicle. With air leveling, a lit level light also means the opposite side or end of the vehicle is high. Two lit yellow level lights mean a corner is low. There should never be three lit yellow level lights or opposing yellow level lights. Like hydraulic leveling, air leveling is Bi-axis. The system always controls two corners of the vehicle at a time. If a side and end light are on, the system will try to turn out the sidelight first. The leveling program begins by trying to level the vehicle by lowering the vehicle; exhausting air from airbags. If a side level light is on, the system will try to lower the opposite side. If the sidelight goes out and an end light is also on, the system will then try to lower the opposite end. If the level lights will not go out while trying to lower the vehicle, the system will go into a raise mode; inflate airbags.

One of two things will trigger the raise mode; if lowering an end, front or rear, and an airbag pressure switch is tripped, the system will instantly go to the raise mode OR if lowering a side or end, and approximately 45 seconds elapse, the system will then start the raise mode. In either case, once the raise mode is initiated, the system will not return to a lower mode again in that sequence. When the raise mode is started, the system will continue to try to turn out the same level light it was working on at the time the raise mode was started. If that level light is turned out, the system will work on any remaining level light. When all four level lights are off, the vehicle is level within the tolerance of the sensing unit.

4. Excess slope. Excess slope means the system cannot level the vehicle. The EXCESS SLOPE light will only come on if the system is in the automatic leveling mode. The excess slope is if a raise procedure for yellow light is initiated and not interrupted, that same level light does not turn off or even flicker, and approximately 15 minutes elapse. If this happens, the system will indicate the EXCESS SLOPE. No more leveling is attempted.

5. Sleep mode. The sleep mode only functions if the vehicle is successfully leveled in the automatic leveling mode and the system is not turned off. The sleep mode will function even though the ignition is turned off. The sleep mode starts monitoring the level sensor inputs every 30 minutes after a successful automatic leveling sequence is completed. If a level sensor input is detected on for a full 2 minutes, the system will wake up and attempt to re-level the vehicle. The original leveling program is used in the sleep mode, lowering first and then raising if necessary. If the vehicle is successfully leveled, the sleep mode will continue. Any time the EXCESS SLOPE light is on, the sleep mode will not function.

3-3 Leveling a non-motorized vehicle. Leveling a non-motorized vehicle is, for the most part, the same as the motorized procedure. We use two jacks at a time for leveling. The yellow level lights indicate a low end, side or corner. All level lights off indicate the vehicle is level within the tolerance of the level sensing unit. The vehicle is stabilized after the leveling process is complete. Excess slope works the same. One basic rule for leveling a non-motorized vehicle is that the trailer must be unhitched from the tow vehicle before leveling the trailer. This means the landing gear, the two front jacks, are going to be on the ground, supporting the trailer before the leveling process begins. This is one difference from leveling a motorized vehicle. Another difference stems from the landing gear being on the ground before the leveling process is started. When leveling a non-motorized vehicle, the vehicle is leveled front to rear first (if needed) and then side to side. The following are items that are specific to non-motorized leveling systems.

1. There will not be an ignition or park brake. Although trailers will not have an ignition it is recommended that there is a master power switch for the leveling system. If a master power switch is used, it must be on to operate the system.

2. The landing gear will be on the ground before the leveling process begins. An automatic leveling system for non-motorized vehicles must see a landing gear pressure switch before automatic leveling can be initiated.

3. The front of the trailer should be lowered before the leveling process is started. If the rear yellow level light is on, an automatic system will lower the front of the vehicle to turn the rear level light off. With a manual system, the front of the trailer should be lowered to turn out the rear level light before leveling the vehicle side to side.

4. Level the vehicle front to rear before side to side. If a front or rear light is lit, the vehicle should be leveled to turn this light out before leveling the vehicle side to side if needed.

5. The trailer should be hitched to the tow vehicle before storing the jacks. The “STORE” function for touch panel controlled systems will not function unless the pressure switches for both front jacks/landing gear are off. It is recommended to take the weight of the trailer off the rear jacks before hitching the trailer to the tow vehicle