Unique Features and Diagnostic Aids

Easy Install™ Features!

1. Replaceable Relays

The ES-50 series controllers come with replaceable relays for improved

reliability.

2. Replaceable fuse

The Es-50 has a built-in 10 amp automotive blade style fuse, for added protection.

3. Terminal Blocks

The ES-50 series has Quick connect wire terminal blocks for easy installation.

4. Two-Wire Speed Sensing

Using an isolated speed sensing input via an 8′ harness and plug(included), the system will work in a very “dirty” environment, by minimizing the pick-up of stray electrical noise.

5. Selectable Speed Ranges

This permits greater precision and accuracy of settings.

6. Ability to accept different speed signals

Other engine controllers cannot accept some speed signals because they cannot read the low-frequency pulses, while others cannot cope with the excessive Electro Magnetic Interference (EMI), or electrical noise, associated with some signals. Dynagen Controllers can accept speed signals such as:

◦ Magnetic Pick-up

◦ Engine Alternator

◦ Flywheel alternator

◦ Direct generator output

7. Reverse Polarity Protection If the unit is initially installed correctly, a simple error like changing an engine battery, and mistakenly hooking up the battery leads in reverse could destroy other engine controllers. The DynaGen controllers have built-in reversed polarity protection. It is not necessary to install an external diode, as is the case with competitors’ units.

8. Timer Feature

The ES52 units are identical to the ES51’s, except that they include a built-in

timer function, capable of four configurations. With the ES52, the need for

purchase and hook up of an external timer is eliminated:

i. “Smart Choke” Feature

Output to a choke solenoid is applied during cranking and is disconnected when the starter is disconnected. However, if a cold engine starts to fail because of a further need for choking, the choke solenoid is re-actuated when the engine falls back to crank disconnect speed and is disconnected when the speed picks up and exceeds the crank disconnect speed again.

ii. Preheat Feature

No other Engine Controller of this size has a preheater timer. Additionally, the ES52 has a yellow LED that glows when the preheater output is actuated.

iii. “Engine Slow Output”

A timer output is engaged for a desired time after the engine starts, too (typically) actuate a solenoid on the throttle, to hold engine speed at a low level.

iv. Air Gate Trip on Overspeed

Some diesel engines are prone to “run-away”, and require the closure of an air gate on the air intake, to ensure engine shut down. The air gate trip actuates the air gate solenoid for a fixed period of 10 seconds if an Overspeed condition is sensed.

(NOTE: These Features are all on the same output terminal; DIP Switch settings determine which one of the four features will be enabled. NOTE also that these 4 features are available only on the ES52)

9. Set-up Mode

On selecting the Set-Up Mode, the installer can readily adjust the controller

to the desired settings. Crank disconnect speed is set at 15% higher than the

cranking speed, and Overspeed Trip is set at 15% higher than normal operating

speed, on return to Operating Mode. The Crank and Rest Time potentiometer

adjustment is done by noting the time between flashes of the Overcrank LED. The

pre-heat Time is set by noting the time of operation of the Preheat LED; the

preheat potentiometer is adjusted accordingly.

Smart features that can save your engine!

10. Loss of Speed Signal Detection at Engine Start

If the engine attempts to start and there is no speed signal, the starting sequence is aborted after 3 seconds. This condition will cause the Overspeed LED to flash. An engine started without a speed signal present is open to the serious starter and ring gear damage and to potential Overspeed damage.

11. Loss of Speed Signal Detection During Running

If the speed signal disappears during an engine run condition, the controller will trip the engine, also causing the Overspeed LED to flash. Losing the speed signal could allow the engine to get into an Overspeed condition.

12. Oil Circuit Verification

A DIP switch is used to select operation with, or without an oil pressure switch. If the operation is selected “With” an oil pressure switch, the controller observes the state of the switch, and looks for a “closed” state before the start of cranking since the default state is “close on low oil pressure.” If it does not see a closed circuit, it assumes a faulty oil switch or an error in wiring and does not permit starting to be attempted. The Oil Failure LED will turn on, indicating an “Oil Circuit related Failure.” This is aid at installation, in addition to monitoring the functionality of the Oil Pressure switch at each starting attempt.

13. “Zero Speed Re-Crank”

If the engine is tripped, and then an attempt is made to restart it while still

spinning, the starter is prevented from being energized until the engine has

coasted to Zero Speed. This saves wear and tear on the starter and ring gear.

Other Helpful Features

14. Extra Input

An Auxiliary Input will trip the engine on the presence of a failure condition.

If the engine was tripped because of failure of the Auxiliary Input, the

“Low Oil” LED is caused to flash. With an appropriate sensor, the

Auxiliary Input could shut down the engine if there was an excess environment

temperature, a generator over-voltage condition, high bearing temperature,

etc., without the need for an extra panel.

15. Available for 3.5-30VDC.

16. Rest Time Indication

The green “Engine Running” LED flashes while the controller is in the

starting mode, between crank attempts. This is a safety feature, in that it

tells personnel that the controller is “active.” Personnel are less

likely to start working on an engine when the light is flashing.

17. Provision of “Crank-Heat” (Optional)

When in the “Pre-Heat” timer mode, there is preheat for the desired time prior to the start of cranking. Then there is a one-second delay period, and then the starter circuit is enabled. After 2 seconds of cranking, when the engine has reached the cranking speed, the glow plug is engaged again, for the duration of cranking, to provide “Crank-Heat” for easier starting. Interrupting of the glow plug operation when the engine is being brought up to speed reduces the system voltage drop.

Engine Controller Unit Specifications

Operating Voltage

• 3.5 to 30VDC continuous, pilots outputs via 12Vdc (standard) or 24Vdc (must be specified) plug-in relays.

Operating Temperature

• -40 to 85º C

Physical Attributes

• 3.3″ wide, 3.3″ high, 1.84″ deep

• Weight: 0.65 lbs.

• Aluminum case, epoxy sealed (black)

Lamps

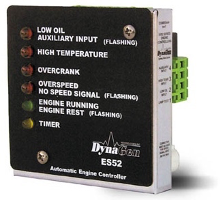

• 5 LED’s (extra “Timer” LED for ES52″) High intensity, regulated brightness

Adjustments

• Crank disconnect: 12 – 4156 Hz (2 ranges)

• Overspeed: 44 – 8492 Hz (2 ranges)

• Crank tries: 1 to 6 times

• Crank/Rest time: 3 to 35 seconds

• Single long crank attempt: up to 256 seconds

Speed Sensing

• Differential input, 8′ of twisted pair cable provided with weatherproof CSA/UL certified plug-in connector

• Input voltage range: 0.1-300Vrms

• Frequency drift: <1% over the entire temperature and voltage range

Protection

• Reversed polarity: no damage, normal operation when normal polarity restored

• Annunciator outputs: auto-reset fuse

• Outputs: Main 10amp fuse provided in the accessible socket

• Inputs: electrostatic discharge protection

• Surge withstand 4500 W for 0.002 sec.

Outputs

• All outputs are sourcing i.e. Switched-to-+Vbat when energized

• Fuel & Starter Outputs: Replaceable relay, outputs rated 5 amp each, continuous

• 12Vdc relay coils provided standard, 24Vdc coils are optional.

• Annunciator outputs: 300 ma per output

Inputs

• Failure inputs: low oil, high temp, auxiliary input – switched-to-ground or switched-to-Bat(+); close to fail

• Lamp test: activates all LED’s (sourcing)

Timers

(ES52 only)

• One malfunction timer output (300 ma sourcing)

• One of four selectable modes: Glowplug (0 – 32 secs), SmartChoke™, Air Gate (10 secs), or Slow (0 – 256 secs)