by Lubrication Engineers

Users of diesel engine oils often note a change in oil pressure when they change from a monograde oil to a multigrade. Typically, oil pressure is lower with a multigrade, and the uninitiated user can interpret the pressure drop as indicating a problem with the engine.

However, low oil pressure is not necessarily bad. In fact, it can be beneficial to a diesel engine operating within normal limits. By the same token, high oil pressure is not necessarily good. It can be caused by blocked oil galleries or a too viscous lubricant. The following guidelines will help you decide whether the oil pressure readings you are getting are the reason for concern.

Oil pressure is caused by the oil’s resistance to flow. Therefore, wide oil galleries and low oil viscosity permit oil to flow freely. The results would be low oil pressure and more reliable lubrication. Conversely, narrow oil galleries (either by design or blockage) and high oil viscosity cause lower oil flow. While oil pressure would be high, lubrication would not be as efficient. A “good” oil, therefore, has viscosity characteristics sufficient to provide good hydrodynamic lubrication and also flows freely around the engine to maintain a continuous supply of lubricant.

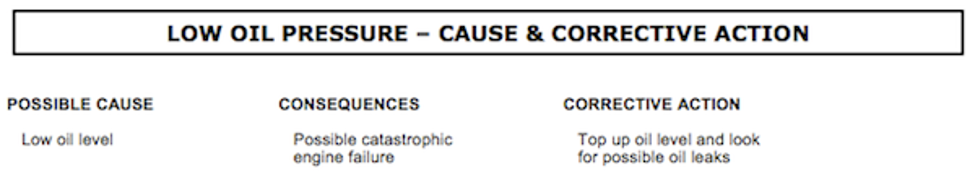

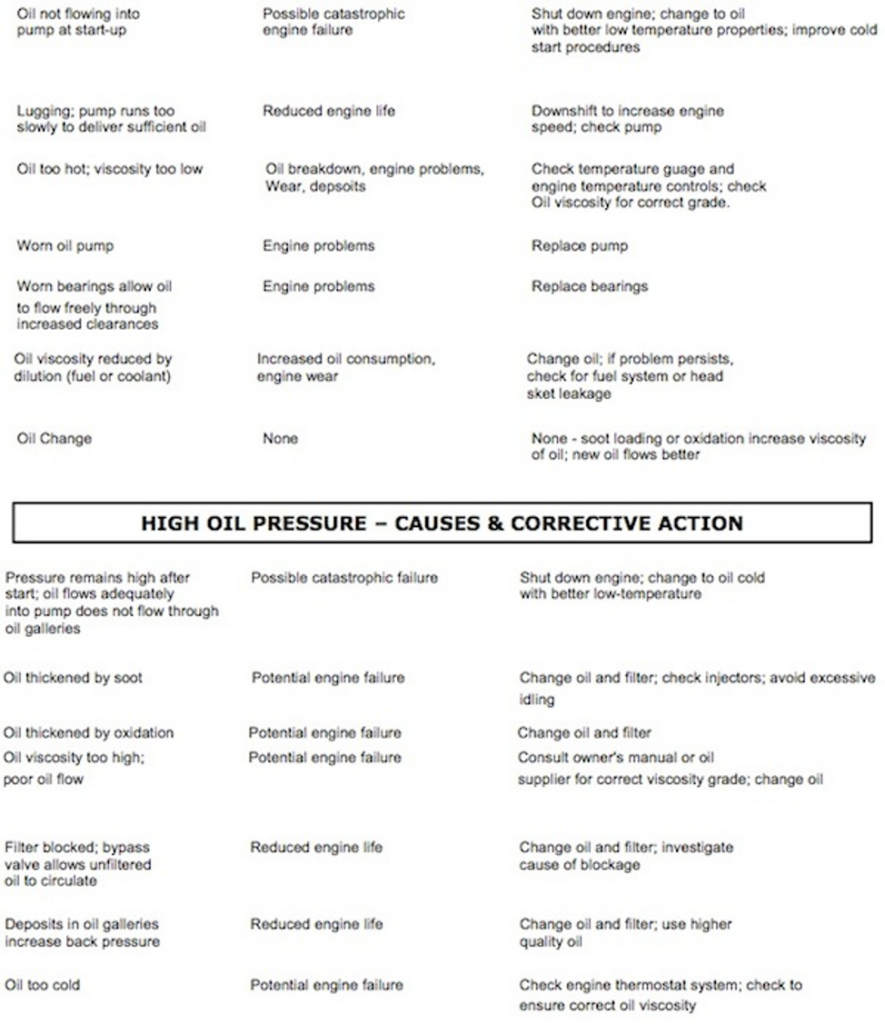

Under ideal conditions, oil pressure should be stable, and any large increase or decrease should be investigated. The tables outline possible mechanical causes of low and high oil pressure and the corrective action that should be taken.

Cold start is one operating condition under which oil pressure should be checked. At startup, all the oil is in the sump, and oil pressure is zero. The pump cannot begin to deliver oil or generate pressure until it sucks cold oil through the filter screen and picks up the tube. Hence, cold start lubrication is improved by using a short, wide pick up tube and oil with good cold flow properties, such as a multigrade.

Cold oil generally has high flow resistance; therefore, oil pressure on startup is high. As the oil circulates and warms up, it flows more freely and oil pressure drops to a stable level. Only at this point is the engine being lubricated properly. Until oil pressure stabilizes, wear rates are high because of insufficient oil delivery to the mating surfaces. Therefore, “good” oil is one that reaches a stable oil pressure quickly.

Thus, a user should be equally concerned about high pressure as low pressure. Higher pressure means more work must be done to pump the oil around the engine. This loss of efficiency should be minimized. In general, high oil pressure does not equal good oil flow; in many cases, it indicates just the opposite. Lower oil pressure, on the other hand, means that the oil is flowing rapidly around the engine. In most cases, this condition is desirable to minimize wear. (see Trouble-Shooting Chart)