by Barry and Cindy 1997 U270 36′ 1-8-11

With all the talk about dipstick housing breaking on Cummins C-8.3 and maybe other engines, I made some braces for ours. Photos taken from a ground view looking up at bottom of the engine are attached. Our engine has several unused threaded mounting holes that I took advantage of.

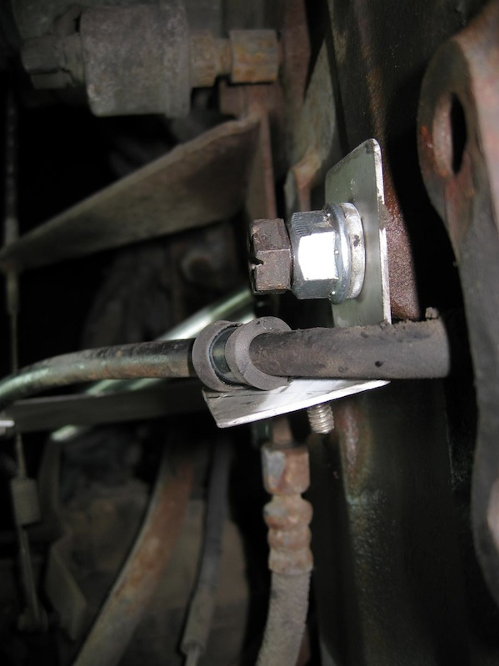

Here are 2 pictures of the dipstick tube bracket that I made to support the tube where it goes into the block. I bought all the stuff at Lowes for about $11. Have more than enough left over to do another one. It took me a while to figure out that the bolt I needed to fasten it to the block was an M12-1.75 x 25 (metric). The predrilled and threaded holes were full of road crud that had to be removed in order to get the bolt in. The bracket is made of 1/8 x 1 1/2 x 6″ flat steel bent to match the angle of the tube. I just put the metal in a vise and hit it with a hammer to form the angle. A metric flat washer and lock washer was necessary to keep the bolt from bottoming out before it was tight. Jerry Whiteaker 1996 U270 36′

Here is a picture of the dipstick tube bracket that I made to support the tube where it goes into the block. Mark Zettek 1999 U270 Special 40′ CAI