Here are some pics of how I rerouted the freshwater overflow on our 2003. The green and white overflow line ran across the tops of the gray and black tanks on the driver’s side. The outlet is just in front of the back tire. You can gain access to this area by removing the panels that cover the sewer valve area.

I plugged the old hole in the bay with a 1″ PVC end cap. Then I extended the green/white hose with a 1″ x 5′ “fit-all corrugated drain hose” for a clothes washer that I found at the local hardware store. I used a 3/4″ PVC coupling and a couple of hose clamps to make a secure connection. In my coach, there was enough room to run the new hose down the front of the black/gray tanks and then to the floor behind the dump valves. I cut a 1 1/2″ hole in the floor and glued in a 1″ ID PVC coupler with 3M 4200 sealer. The coupler was long enough to extend out the bottom about 1/8″ and gave a good surface to seal it with the 4200. I covered the end of the new hose with a fiberglass screen and secured it with a hose clamp on the inside. I’ll probably add another hose clamp to the outside when the 4200 is fully cured.

I couldn’t find the green/white hose, but did find some flexible hose at a big box store that worked very well it’s 1 1/2″. I used a 1″ schedule 40 or 80 (can’t remember) nipple for the “through the hull” fitting.

I bit the bullet today and finally installed my version of the overflow bypass system. While doing so I removed the carpeted partition in front of the grey and black tanks, and I presumed, the mani-bloc. To my surprise, my ’92 U-280 doesn’t have one, just the sensors for the two tanks. I guess that’s one less system I have to worry about. After triple-measuring the location to cut the hole in the floor, it took less than 20 seconds to go through the layers. I lucked out and didn’t hit any frame members.

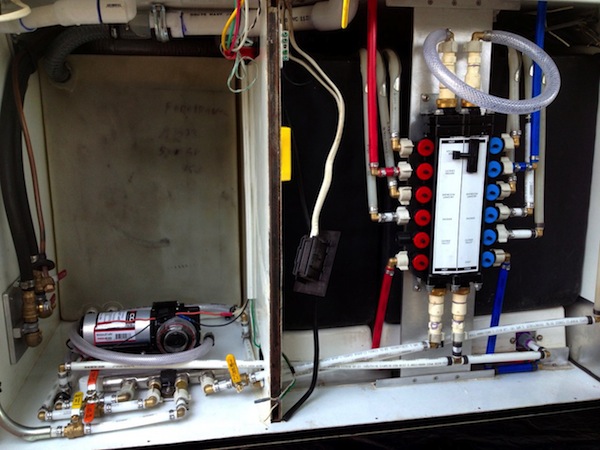

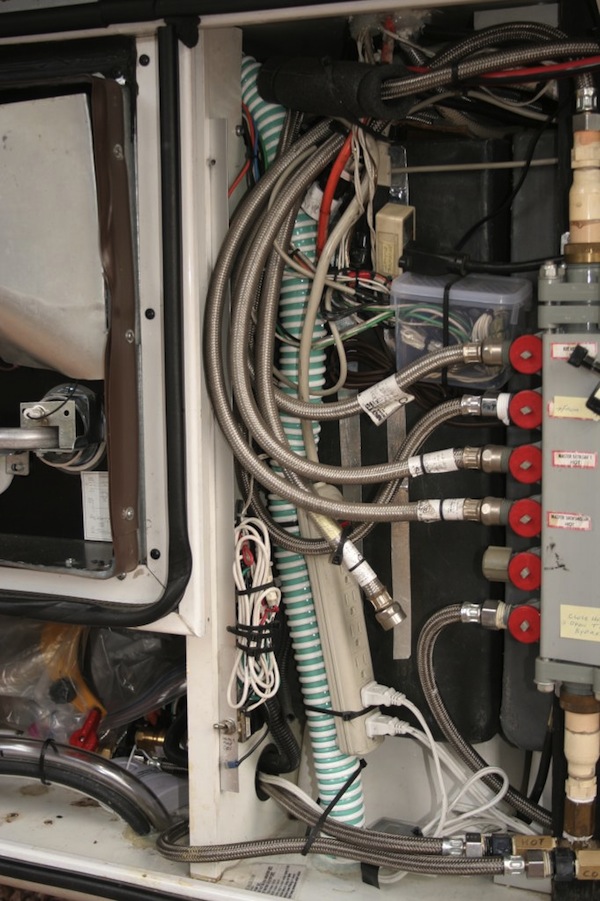

Since I have had everything out of the freshwater compartment, putting it back together from a blank slate creates some opportunities to make changes that wouldn’t otherwise be feasible. I have routed the Vent/Overflow up through the floor and looped it back down through the original bulkhead penetration. I ran a 1″ PVC pipe down the backside of the bulkhead to be able to direct the overflow away from the bulkhead joint. Time will tell if this will be a successful strategy or not, but I am betting that it will function as I designed it to. I put in a tee in the loop with a riser and an inline vent inside of the laundry hook up the cavity. I could of course short circuit the loop and run the overflow right through the bulkhead and still have the benefit of the pipe to direct the water away from the bulkhead joint, but I would first have to take the water heater out to accomplish this.