12 Volt 1/3 hp air compressor – Mfg Part # 070025

TA-4101 DC Compressor output

| PSI | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| CFM | 2.20 | 1.95 | 1.75 | 1.58 | 1.45 | 1.34 | 1.25 | 1.17 | 1.10 | 1.03 | .95 |

| Compressor and motor performance data | ||

| Max Cont Pressure: 100 PSI | Motor Voltage: 12V DC | Motor Type: Permanent magnet |

| Max restart Pressure: 100 PSI | Current at rated load: 28 A | Full load speed: 1800 RPM |

| Max Ambient Air Temp: 104 F | Power at Rated Load: 340 W | Horsepower: 1/3 |

| Min Ambient Start Temp: 50 F | Starting Current (locked rotor): 198 A | Weight: 22 pounds |

Operations

AMBIENT CONDITIONS:

Pumps should be operated in a well-ventilated area where the surrounding air is relatively clean, dry and temperatures are consistently within the range of 35’F to 95’F.

ELECTRICAL:

The unit must be wired in accordance with local electrical codes. The unit must be protected by a separate over-current protector (fuse) located in the positive (+) lead wire from the power source. Wire size to be minimum 8 gauge. The fuse should be based upon 115% of full motor load.

MOTOR:

Electrical connections must be made using ring type connectors. All connections must be electrically, mechanically, and galvanically sound to withstand vibration and movement encountered in normal service.

FILTERS:

Do not operate pumps without an inlet air filter. Excessive dirt, foreign particles, moisture, or liquids entering the pump can contribute to poor performance and/or premature failure. Dirty filters reduce pump performance by restricting airflow. Inspect filter elements periodically and clean or replace when necessary.

DO NOT CLEAN FILTER ELEMENTS WITH PETROLEUM BASED PRODUCTS.

WARNING- These products are suitable for pumping only atmospheric air. As defined in Compressed Gas Association Pamphlet G-7, Page 3, atmospheric air is a mixture of elements and compounds where nitrogen and oxygen comprise more than 99% with all other trace gases comprising less than 1 %.

DO NOT USE THIS PRODUCT IN CONTAMINATED ENVIRONMENTS OR FOR PUMPING MIXTURES OTHER THAN ATMOSPHERIC AIR.

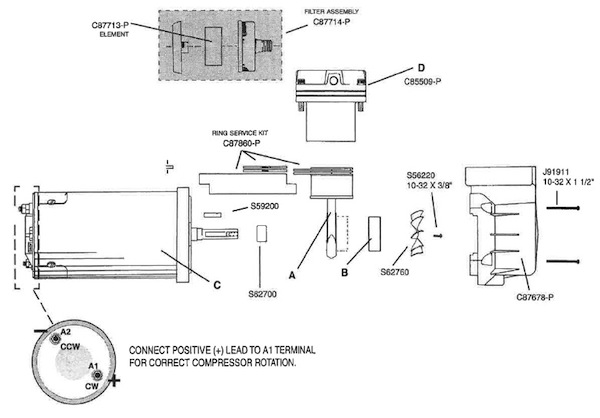

C85493-P Minor Service Kits (Includes C85485-P Valve Assembly Kit and C87860-P Ring Service Kit) – replace at 6000 hours continuous duty/maximum pressure (33% duty cycle =2+ years).

Major Repair Kit (Includes C85493-P Minor Kit and Piston Rod Assembly. Kit Part Number on Front) – replace at 12000 hours of continuous duty/maximum pressure.

C85517-P Brush Kit – (needs 2) Replace at 1000 – 2000 hours. $38 X 2 = $76

Parts List

NOTE: Teflon Tape is not recommended when installing intake filters.

Only a few basic maintenance details are required to ensure trouble-free operation.

FILTRATION:

Dirty Filters reduce pump performance. Periodically check the inlet air filter. To clean the filter, disassemble filter housing and use compressed air to blow dirt particles from the filter element. Replace filter when an element can no longer be cleaned with this method.

LUBRICATION:

The Taskair line of piston products is a dry, oil-less compressor/pump design. This product uses sealed grease packed bearings and does not require additional lubrication.

CAUTION: DO NOT LUBRICATE, Adding greases or petroleum products to this unit will reduce performance and can potentially damage the product.

SERVICE KIT:

Thomas has available from stock minor service kits for Taskair series motor compressors. To obtain these service kits please contact the factory for the Taskair representative nearest you.

C85493-P minor service kit includes Piston rings, springs, skirt, cylinder head gasket, and (2) valve reeds.

NOTE: For complete compressor rebuild, order (1) one minor service kit plus appropriate piston/rod assembly.